В современной промышленности, где каждая секунда и каждый ресурс на счету, производительность становится ключевым фактором успеха. Один из наиболее критических аспектов в процессах обработки материалов, особенно в металлообработке, — это эффективное управление теплом, генерируемым во время сверления. Инновационные системы охлаждения сверл не просто улучшают этот процесс; они кардинально трансформируют его, приводя к значительному повышению производительности, снижению затрат и улучшению качества конечной продукции. В этой статье мы глубоко погрузимся в мир этих систем, исследуя их принципы работы, преимущества, последние технологические достижения, практические применения и будущие тенденции, чтобы предоставить вам полное понимание того, как они могут революционизировать ваши операции.

Сверление — это фундаментальная операция в многих отраслях, от машиностроения и аэрокосмической промышленности до строительства и электроники. Однако при сверлении, особенно твердых материалов, таких как сталь, титан или композиты, возникает значительное трение, которое генерирует тепло. Это тепло может привести к множеству проблем: ускоренному износу сверла, снижению точности отверстий, деформации материала и даже поломке инструмента. Традиционные методы охлаждения, такие как использование смазочно-охлаждающих жидкостей (СОЖ) вручную или через простые системы, часто оказываются недостаточными для эффективного управления теплом в высокоскоростных или тяжелых условиях.

Инновационные системы охлаждения сверл представляют собой передовые решения, которые интегрируют охлаждение непосредственно в процесс сверления. Они используют технологии, такие как внутренняя подача охлаждающей жидкости через каналы в сверле, системы туманообразования, криогенное охлаждение или даже лазерное辅助ное охлаждение. Эти системы разработаны для точного контроля температуры в зоне резания, что позволяет поддерживать оптимальные условия для инструмента и материала. В результате, они не только продлевают срок службы сверл, но и позволяют увеличить скорости резания, улучшить качество поверхности и снизить энергопотребление.

Исторически, системы охлаждения эволюционировали от простого применения СОЖ к сложным, автоматизированным системам, которые являются неотъемлемой частью современных CNC станков. Ранние попытки охлаждения включали использование воды или масла, но с развитием материалов и технологий, стали появляться более эффективные методы. Например, в 1960-х годах начали внедряться системы с внутренней подачей жидкости, а в последние десятилетия, с ростом вычислительной мощности и датчиков, системы стали умнее, способными адаптироваться к реальным условиям в режиме реального времени.

Сегодня, инновационные системы охлаждения — это не просто дополнительная опция; они становятся стандартом в высокопроизводительных производствах. Их важность подчеркивается растущим спросом на более эффективные и экологичные производственные процессы. В условиях глобальной конкуренции, компании, которые внедряют такие системы, часто получают значительное преимущество, снижая время простоя, улучшая точность и сокращая общие затраты на эксплуатацию.

Чтобы понять, как инновационные системы охлаждения сверл повышают производительность, необходимо разобраться в их основных принципах работы. Эти системы основаны на фундаментальных законах теплопередачи и механики резания, но используют современные технологии для их оптимизации.

Во-первых, тепло при сверлении генерируется primarily due to friction between the drill bit and the workpiece, as well as plastic deformation of the material. This heat can cause the drill bit to overheat, leading to thermal softening, which reduces its hardness and wear resistance. Additionally, high temperatures can alter the microstructure of the workpiece, causing issues like work hardening or residual stresses. Effective cooling aims to remove this heat quickly, maintaining the tool and material within their optimal temperature ranges.

Инновационные системы часто используют внутренние каналы для подачи охлаждающей жидкости непосредственно к режущим кромкам сверла. Это позволяет жидкости достигать самых горячих точек, где тепло генерируется наиболее интенсивно. Жидкость, обычно вода-based или oil-based СОЖ, absorbs the heat and carries it away, either through evaporation or circulation. In some advanced systems, the coolant is pressurized to ensure it reaches deep into the hole, even in deep drilling applications.

Another principle is the use of mist cooling or minimum quantity lubrication (MQL), where a fine mist of coolant is applied. This method reduces the amount of coolant used, making it more environmentally friendly and cost-effective, while still providing adequate cooling. MQL systems often incorporate air to atomize the coolant, creating a mist that can penetrate small spaces and provide efficient heat transfer.

For extreme conditions, cryogenic cooling systems use liquified gases like nitrogen or carbon dioxide to achieve very low temperatures. These systems can supercool the drill bit, preventing thermal damage entirely. However, they require specialized equipment and are more complex to implement.

Additionally, some innovative systems integrate sensors and feedback loops. For example, temperature sensors monitor the heat in real-time, and the system adjusts the flow rate or type of coolant accordingly. This adaptive cooling ensures that cooling is optimized for varying conditions, such as changes in material hardness or drilling speed.

The principles also involve material science. Advanced drill bits are made from materials like carbide or coated with ceramics that have high thermal conductivity, allowing heat to dissipate more easily. When combined with effective cooling systems, these materials further enhance performance.

In summary, the working principles of innovative cooling systems revolve around targeted heat removal, efficient fluid delivery, and adaptive control. By addressing the root causes of heat generation, these systems enable higher productivity by allowing faster drilling speeds, longer tool life, and better quality outcomes.

Внедрение инновационных систем охлаждения сверл приносит множество преимуществ, которые directly translate to increased productivity. Let's explore these benefits in detail.

First and foremost, these systems significantly extend tool life. By keeping the drill bit cool, they reduce wear and tear caused by thermal fatigue and abrasion. Studies have shown that proper cooling can increase tool life by up to 50% or more, depending on the application. This means fewer tool changes, reduced downtime, and lower costs for replacement tools. In high-volume production environments, this can lead to substantial savings over time.

Second, innovative cooling allows for higher cutting speeds and feed rates. When heat is managed effectively, the drill bit can operate at its maximum potential without the risk of overheating. This directly increases the material removal rate, leading to faster completion of drilling operations. For instance, in aerospace industries where drilling hard materials like titanium is common, advanced cooling systems enable speeds that were previously impossible, cutting production times significantly.

Third, improved product quality is a major benefit. Effective cooling prevents thermal damage to the workpiece, such as burns, cracks, or dimensional inaccuracies. This results in holes with better surface finish, tighter tolerances, and reduced need for post-processing. In precision industries like medical device manufacturing, this is crucial for meeting strict quality standards.

Fourth, these systems enhance safety by reducing the risk of tool failure and accidents. Overheated drill bits can break suddenly, causing damage to machinery or injury to operators. By maintaining stable temperatures, cooling systems minimize such risks, contributing to a safer work environment.

Fifth, environmental and economic advantages are prominent. Systems like MQL use less coolant, reducing waste and disposal costs. This aligns with growing sustainability goals in industry. Additionally, by improving efficiency, these systems lower energy consumption per part produced, further cutting costs.

Sixth, versatility is another key advantage. Innovative cooling systems can be adapted to various materials and drilling conditions. Whether drilling soft aluminum or hard alloys, these systems can be tuned to provide optimal cooling, making them suitable for a wide range of applications.

Finally, the integration with smart technologies allows for predictive maintenance. By monitoring cooling performance and tool condition, systems can alert operators before failures occur, preventing unplanned downtime and optimizing maintenance schedules.

In essence, the benefits of innovative cooling systems are multifaceted, touching on cost, quality, safety, and sustainability. By investing in these systems, companies can achieve a competitive edge through enhanced productivity and reliability.

The field of drill cooling has seen remarkable technological advancements in recent years, driven by innovations in materials, electronics, and manufacturing processes. These advancements have made cooling systems more efficient, reliable, and accessible.

One major advancement is the development of smart cooling systems that incorporate IoT (Internet of Things) and AI (Artificial Intelligence). These systems use sensors to collect data on temperature, pressure, and flow rates in real-time. AI algorithms then analyze this data to optimize cooling parameters automatically. For example, if a drill bit starts to overheat, the system can increase coolant flow or switch to a different cooling method without human intervention. This not only improves performance but also reduces the skill required from operators.

Another breakthrough is in the design of drill bits themselves. Modern drills often feature internal coolant channels that are precision-engineered using additive manufacturing (3D printing). This allows for complex geometries that direct coolant exactly where it's needed, improving efficiency. Additionally, coatings like diamond-like carbon (DLC) or titanium nitride enhance thermal conductivity and reduce friction, complementing the cooling systems.

Cryogenic cooling technology has also advanced. Systems now use closed-loop cycles that recycle cryogenic fluids, making them more economical and environmentally friendly. For instance, in applications like drilling composites or superalloys, cryogenic cooling can prevent delamination or thermal cracking, enabling new possibilities in material processing.

Minimum quantity lubrication (MQL) systems have evolved to become more precise. New nozzle designs and control systems ensure that the mist is applied consistently, even in high-speed operations. Some MQL systems are integrated with CNC machines, allowing for programmable cooling patterns based on the toolpath.

Furthermore, there are innovations in coolant formulations. Bio-based and synthetic coolants are being developed that offer better cooling performance while being less harmful to the environment and operators. These coolants often have improved lubricity and thermal stability, enhancing overall system efficiency.

Wireless and remote monitoring capabilities are another trend. Operators can now monitor cooling systems from a distance using smartphones or computers, receiving alerts and making adjustments on the go. This is particularly useful in large manufacturing facilities or unmanned operations.

Lastly, advancements in simulation software allow engineers to model heat generation and cooling effects before physical implementation. Tools like finite element analysis (FEA) help in designing optimal cooling strategies, reducing trial and error and speeding up innovation.

These technological achievements are pushing the boundaries of what's possible in drill cooling, making systems more adaptive, efficient, and integrated into the broader smart manufacturing ecosystem.

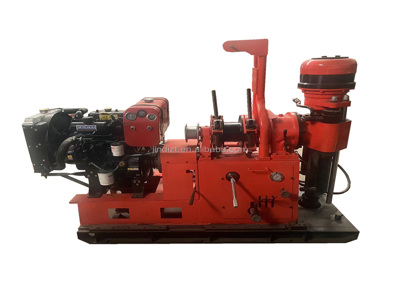

Инновационные системы охлаждения сверл нашли применение в myriad industries, each with unique challenges and requirements. Let's explore how these systems are used in practice across different sectors.

In the automotive industry, where high-volume production is common, cooling systems are essential for drilling engine blocks, transmission components, and chassis parts. For example, in drilling cast iron or aluminum, internal coolant systems allow for continuous operation at high speeds, reducing cycle times and improving consistency. This leads to faster assembly lines and lower costs per vehicle.

The aerospace sector relies heavily on these systems for drilling tough materials like titanium and nickel-based alloys. These materials generate intense heat, and without effective cooling, tool life would be极短. Advanced cooling systems, often cryogenic or high-pressure, enable precise drilling of aircraft frames and engine components, ensuring safety and reliability. In fact, in the production of jet engines, cooling systems are critical for maintaining dimensional accuracy in critical holes.

In the medical device industry, precision is paramount. Cooling systems are used in drilling surgical instruments, implants, and diagnostic equipment. For instance, when drilling stainless steel or titanium for bone screws, MQL systems provide just enough cooling to prevent thermal alteration of the material, which could affect biocompatibility. This results in higher-quality products that meet stringent regulatory standards.

The energy sector, including oil and gas, uses these systems for drilling components in harsh environments. For example, in offshore drilling equipment, cooling systems help manage heat when drilling through hard rock formations, extending tool life and reducing maintenance needs during operations.

In general manufacturing and metalworking, cooling systems are ubiquitous. From small workshops to large factories, they improve efficiency in drilling operations for everything from machinery parts to consumer goods. The adaptability of these systems means they can be customized for specific materials, such as plastics or composites, where overheating can cause melting or deformation.

Even in emerging fields like additive manufacturing, cooling systems are being integrated into drilling post-processing steps. For example, after 3D printing metal parts, drilling may be needed for assembly, and cooling ensures that the printed material's properties are not compromised.

Case studies abound: A company in Germany reported a 30% increase in drilling productivity after adopting an AI-driven cooling system for their CNC machines. In the USA, an aerospace manufacturer reduced tool costs by 40% by switching to cryogenic cooling for titanium drilling.

These practical applications demonstrate that innovative cooling systems are not niche technologies but essential tools that drive productivity across the industrial landscape.

The future of drill cooling systems is bright, with several trends poised to further enhance productivity and sustainability. As technology continues to evolve, we can expect even more innovative solutions.

One major trend is the increased integration of AI and machine learning. Future systems will not only react to conditions but predict them. By analyzing historical data, AI could forecast tool wear or thermal issues before they occur, allowing for proactive adjustments. This will make cooling systems more autonomous and reliable.

Another direction is the development of green cooling technologies. With growing environmental concerns, there is a push towards coolants that are biodegradable and non-toxic. Research is underway on using natural substances or advanced synthetics that offer superior cooling with minimal ecological impact. Additionally, energy-efficient systems that reduce power consumption will become more prevalent.

Nanotechnology holds promise for future cooling systems. Nanofluids, which are coolants with suspended nanoparticles, have shown higher thermal conductivity than traditional fluids. Integrating nanofluids into cooling systems could dramatically improve heat transfer efficiency, allowing for even higher performance in compact designs.

Additive manufacturing will play a bigger role in customizing cooling systems. 3D printing enables the creation of complex internal channels in drill bits that are tailored to specific applications. This could lead to bespoke cooling solutions for unique industrial needs.

The rise of digital twins—virtual replicas of physical systems—will allow for real-time simulation and optimization. Engineers could test different cooling strategies in a virtual environment before implementing them, reducing costs and speeding up innovation.

In terms of market trends, we can expect greater adoption in small and medium-sized enterprises (SMEs) as costs decrease and technology becomes more user-friendly. Cloud-based monitoring and control will make advanced cooling accessible to a wider audience.

Finally, interdisciplinary approaches, such as combining cooling with other technologies like ultrasonics or lasers for assisted drilling, could open new frontiers. For example, laser cooling might be used to pre-cool materials before drilling, reducing overall heat generation.

These future innovations will continue to push the boundaries, making drill cooling systems even more integral to high-productivity manufacturing.

В заключение, инновационные системы охлаждения сверл представляют собой transformative technology that significantly boosts productivity across various industries. By effectively managing heat, these systems extend tool life, enable higher speeds, improve quality, enhance safety, and promote sustainability. With ongoing technological advancements and future trends pointing towards smarter, greener, and more efficient solutions, the potential for further gains is immense. Companies that embrace these systems will not only see immediate benefits in their operations but will also be better positioned for the challenges of tomorrow's manufacturing landscape. Investing in innovative cooling is not just an upgrade; it's a strategic move towards unparalleled productivity and competitiveness.